TECHNOLOGY

The Use of Iodine

An alternative propellant showing comparable performance to xenon that doesn’t require a pressurised storage system and is 100x cheaper, thus resulting in lower overall costs.

GREEN

PROPELLANT

VERY HIGH

DENSITY

SOLID

AT ROOM TEMPERATURE

TECHNOLOGY ADVANTAGES

Which are the advantages of iodine over other propellants?

REDUCED PROCUREMENT COSTS

Critical propellants as krypton and xenon are more and more expensive and less and less available. Xe is a trace gas in the atmosphere (<0.1 ppm) and its limited production, as a by-product of air separation, is an expensive process (2000-5000 €/kg). Kr is more abundant (about 1 ppm) than Xe in the atmosphere and can be more than 10-times cheaper (300 €/kg). But its production in Europe is too limited and its propulsive performance is too low to be considered as a safe alternative for electric propulsion. Iodine propellant has the potential to overcome these issues, given that it is abundant in Earth’s crustal rocks (0.46 ppm) and far less expensive than Xe (30 €/kg).

VERY HIGH DENSITY

It is proven that iodine and xenon show comparable propulsive performance, unlike other alternative propellants as air and water, but the density of iodine is three times higher than xenon, thus a higher total impulse is achievable for the same volume of propellant. This feature extends the thruster’s capability to much larger total delta-V missions, meeting the more and more demanding mobility needs of SmallSats.

SOLID AT ROOM TEMPERATURE

Iodine is solid at ambient conditions; thus, no cryogenic or strict thermal control is required when the thruster is off.

UNPRESSURIZED SYSTEM

The possibility to be stored in non-pressurized tanks undertakes the capability of iodine storage systems to be optimized in function of the available space inside the satellite platform, guaranteeing flexibility and compactness thanks to its cubic shape.

EASIER HANDLING AND STORAGE OPERATIONS

A propulsive unit filled with iodine can be integrated into the satellite before qualification or acceptance tests. The satellite can be shipped to the test facilities and to the launch sites without any transportation issues because of pressure or temperature monitoring.

XENON VS IODINE

The use of iodine instead of xenon ensures the compactness of the design, considering that the volume of xenon, for the same total impulse, is more than 2x of the volume of iodine and in addition the iodine does not need a pressurized tank, with all its consequent drawbacks.

|

|

REGULUS-50-Xe |

REGULUS-50-I2 |

|

State of the propellant

|

Supercritical (77.5 bar, 30 °C)

|

Solid

|

|

ρ [kg/m3]

|

1260

|

4940

|

|

Itot [Ns]

|

3000

|

3000

|

|

Mprop [kg]

|

0.51

|

0.56

|

|

Vprop [l]

|

0.24

|

0.11

|

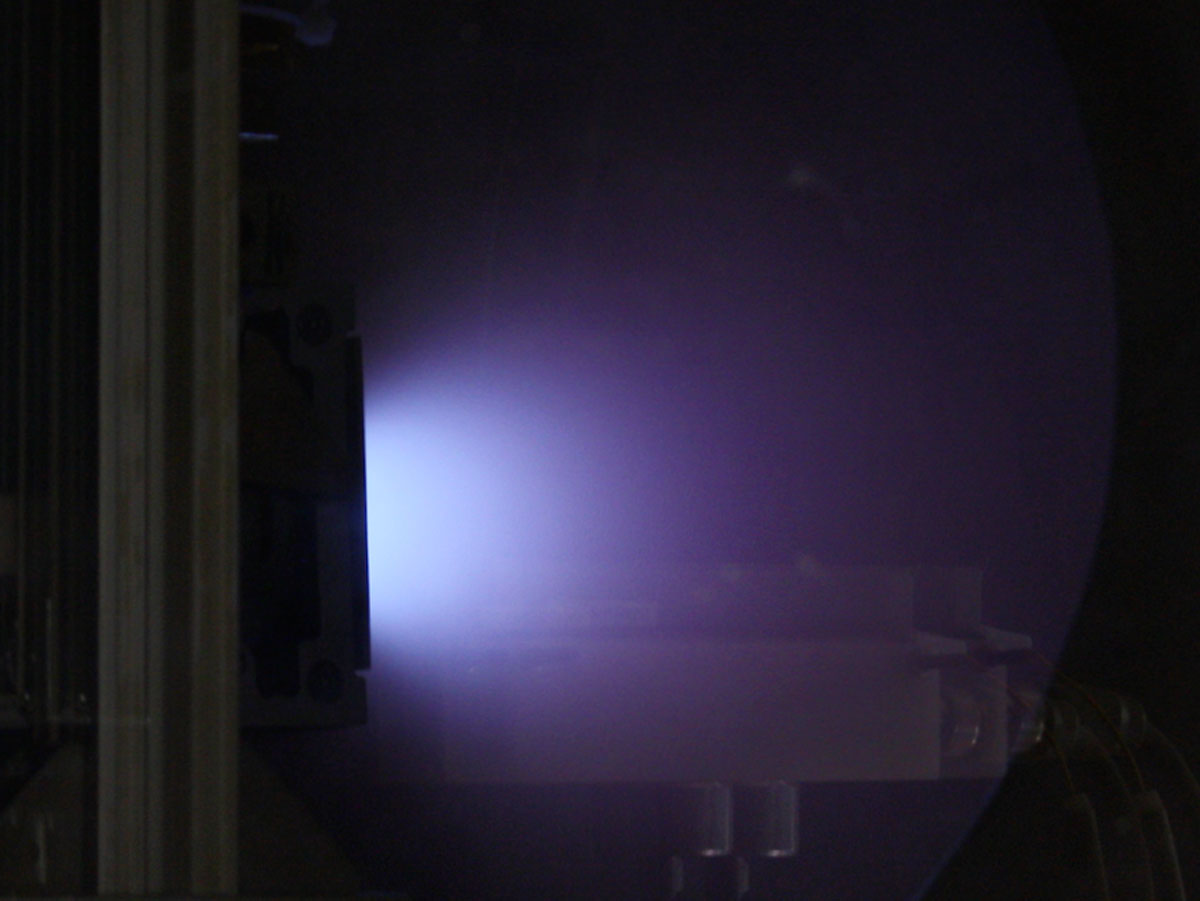

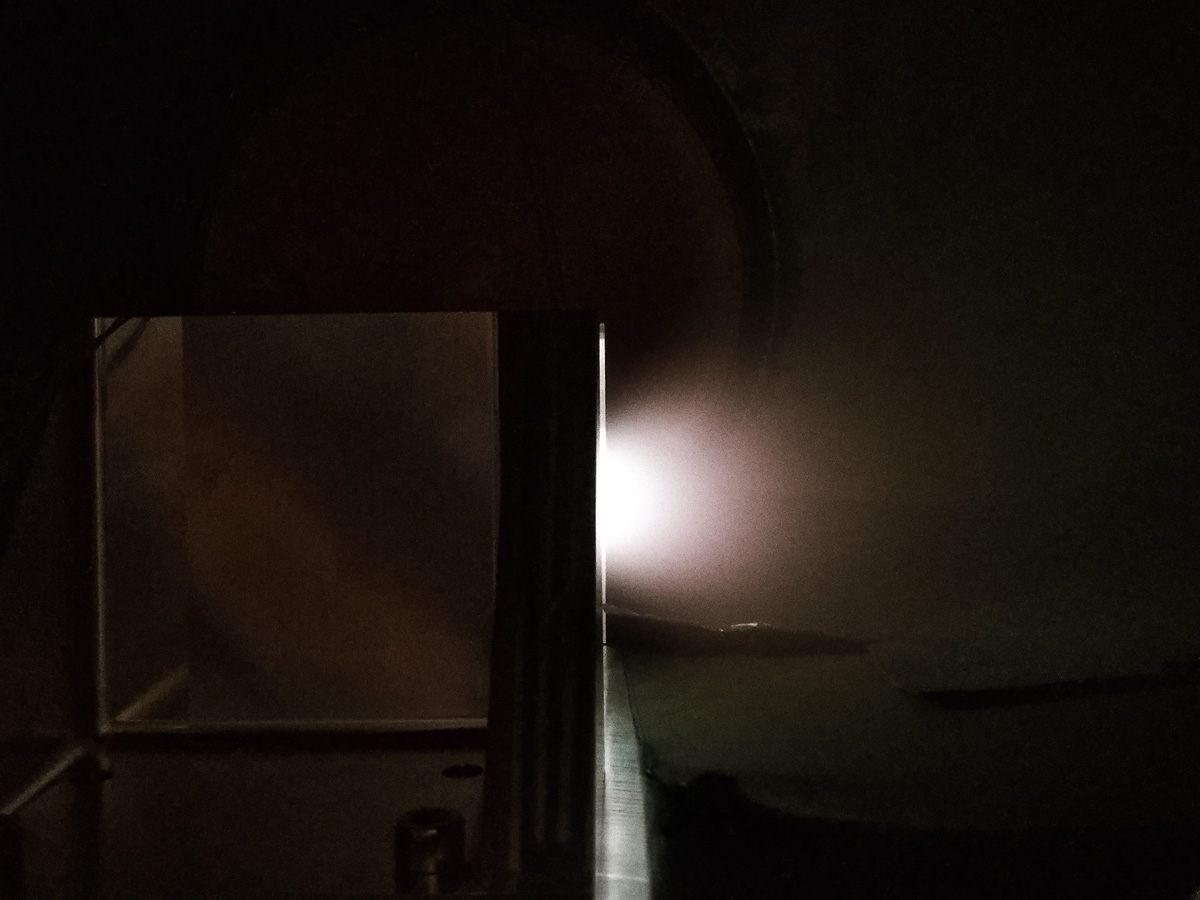

REGULUS-50-Xe.

REGULUS-50-I2.

FUNDED PROGRAMS: FIT

Prompted by the rapidly growing interest of the electric porpulsion community towards the iodine, ESA-EPL decided to upgrade its FEEP vacuum facility to enable testing with iodine-fed thrusters. ESA acknowledged T4i extensive expertise with iodine selecting T4i for this activity. The FIT system employs a custom beam dump to capture the iodine plume ejected by the thrusters during the tests in order to prevent the chemical aggression of hot iodine vapors. Iodine is later removed from the facility by a dedicated sub-system, without direct exposure of operators. FIT was successfully delivered to EPL and commissioned in december 2022, with its first operational test scheduled for late 2023. T4i will participate to the test by providing a REGULUS-50-I2 system to EPL and by assisting EPL personnel during the activity.